2-Piece Forged Wheels: Modular Excellence by Forgex Speed

Page Introduction: An Overview of 2-Piece Forged Wheels

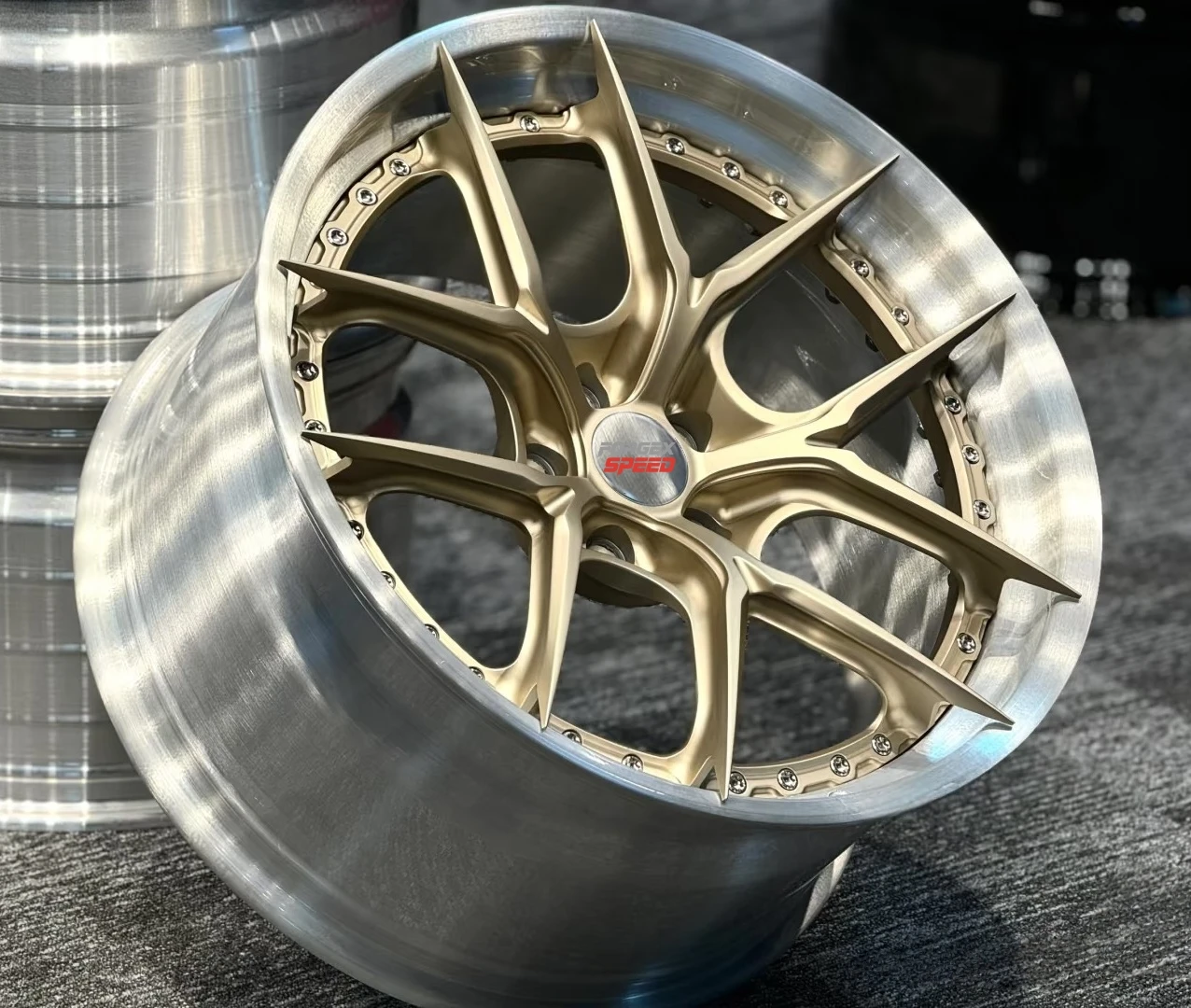

In the world of automotive customization and performance, 2-Piece Forged Wheels have emerged as the gold standard for enthusiasts who demand both head-turning aesthetics and reliable performance—and Forgex Speed’s iteration of this category elevates the concept to new heights. 2-Piece Forged Wheels are a specialized automotive wheel design that splits the structure into two key components: a forged center section and a separate outer barrel, both engineered to work in perfect harmony. Forgex Speed’s 2-Piece Forged Wheels refine this modular approach by using premium 6061-T6 aluminum for both the center and barrel, paired with high-pressure 12K-Ton Forging to ensure uncompromising strength. This design isn’t just about looks—it’s a strategic combination that unlocks deep-lip profiles, adjustable widths, and endless custom aesthetic combinations, making these 2-Piece Forged Wheels the top choice for VIP builds, widebody setups, stance-focused projects, and luxury show cars.

Unlike monoblock forged wheels (which are crafted from a single piece of aluminum), 2-Piece Forged Wheels thrive on modular flexibility. Forgex Speed’s design separates the forged 6061-T6 aluminum center from the outer barrel, allowing for unparalleled customization that monoblock wheels simply can’t match. Enthusiasts aren’t limited to pre-set sizes or styles—instead, they can mix and match center designs with different lip depths, choose hardware finishes that complement their vehicle’s color scheme, and adjust widths to fit aggressive offsets. This flexibility is a game-changer for custom builds: a VIP-style luxury sedan can sport deep-lip 2-Piece Forged Wheels for a sophisticated stance, while a widebody sports car can leverage adjustable barrel widths to fill flared fenders perfectly. Beyond aesthetics, Forgex Speed’s 2-Piece Forged Wheels don’t sacrifice performance—each component is forged to deliver the same strength as monoblock alternatives, with the modular structure adding unique advantages like easier repair and personalized fitment.

What truly distinguishes Forgex Speed’s 2-Piece Forged Wheels is the balance between customization and quality. Every center section and barrel undergoes 12K-Ton Forging to compress the 6061-T6 aluminum, eliminating internal voids and aligning the metal’s grain structure for maximum rigidity. The modular connection between center and barrel uses high-strength hardware (like titanium or stainless steel bolts) that’s engineered to handle the stresses of street driving and show car display alike. Whether you’re a builder crafting a one-of-a-kind showstopper or a driver who wants wheels that reflect their personal style without compromising reliability, Forgex Speed’s 2-Piece Forged Wheels deliver. They aren’t just wheels—they’re a customizable canvas that merges premium engineering with individual expression.

Core Advantages: Why Choose Forgex Speed 2-Piece Forged Wheels

1. Unmatched Styling Flexibility: Customize to Your Vision

The most defining advantage of Forgex Speed’s 2-Piece Forged Wheels is their unmatched styling flexibility, made possible by the modular separation of center and barrel. Unlike monoblock wheels, which lock you into a single pre-designed shape, 2-Piece Forged Wheels let you tailor every visual aspect to match your build’s unique vibe. Forgex Speed offers a wide range of center designs—from sleek, minimalist spokes to intricate, multi-spoke patterns—each forged from 6061-T6 aluminum for both strength and style. But the real customization lies in the barrel options: you can choose lip depths ranging from subtle 1-inch profiles to dramatic 4-inch deep lips that create a “flush” stance, a hallmark of VIP and stance builds.

Hardware customization adds another layer of personalization. Forgex Speed offers hardware finishes like black anodized, polished stainless steel, and gold-plated bolts, allowing you to match the wheels to your vehicle’s trim, brake calipers, or exterior accents. Even the assembly configuration can be adjusted—you can opt for a “reverse mount” setup to push the lip further outward for a more aggressive look, or a standard mount for a classic appearance. This flexibility means no two sets of Forgex Speed 2-Piece Forged Wheels have to be the same. Whether you’re building a luxury Mercedes-Benz with a refined stance or a widebody Toyota Supra with a bold, track-inspired look, these wheels can be customized to fit your vision perfectly. For enthusiasts who refuse to settle for off-the-shelf styling, this flexibility is invaluable.

2. Deep-Lip Construction: Elevate Visual Impact

Forgex Speed’s 2-Piece Forged Wheels are engineered for deep-lip construction—a key feature that elevates the visual impact of any vehicle. Deep-lip wheels have long been a staple of custom automotive culture, as they create a wide, low-slung stance that makes vehicles look more aggressive and refined. The modular design of 2-Piece Forged Wheels makes deep lips possible: unlike monoblock wheels, which struggle to achieve deep lips without sacrificing strength, the separate barrel component can be forged into deep, curved profiles while the center remains thick and strong.

Forgex Speed’s deep-lip barrels are forged from high-density 6061-T6 aluminum, ensuring they maintain rigidity even with their extended profile. The lip is precision-machined to have a smooth, consistent curve, with no uneven edges or imperfections that can detract from the wheel’s appearance. Whether paired with a luxury sedan or a show car, these deep-lip 2-Piece Forged Wheels draw attention—they fill wheel wells perfectly, complement widebody kits, and make tires look more substantial. The deep-lip design also enhances the wheel’s proportional balance: the wide lip contrasts with the center’s spokes, creating a visually dynamic look that’s both modern and timeless. For drivers who want their vehicle to stand out at car shows or on the street, the deep-lip construction of these 2-Piece Forged Wheels is a must-have feature.

3. Adjustable Widths and Offsets: Perfect Fitment for Aggressive Builds

Fitment is everything in custom automotive builds, and Forgex Speed’s 2-Piece Forged Wheels deliver perfect fitment thanks to adjustable widths and offsets. Aggressive builds like widebody setups, stance projects, or track-focused cars often require non-standard wheel widths and offsets to fill flared fenders, avoid rubbing, and achieve the desired stance. Monoblock wheels rarely offer this level of adjustability, but the modular design of 2-Piece Forged Wheels makes it easy.

Forgex Speed offers barrel widths ranging from 8 inches to 14 inches, allowing you to match the wheel to your vehicle’s fender width—whether you’re running a mild widebody kit or an extreme “wide stance” setup. Offsets can be adjusted by swapping out different center sections or using spacer rings between the center and barrel, giving you control over how far the wheel sits from the hub. This adjustability ensures the wheels clear brake calipers, suspension components, and fenders, even on heavily modified vehicles. For example, a widebody Porsche 911 can use 12-inch wide barrels with a negative offset to fill the flared fenders, while a stance-focused Honda Civic can use a combination of deep lips and positive offset to achieve a “tucked” look. The ability to fine-tune width and offset makes Forgex Speed’s 2-Piece Forged Wheels the most versatile option for aggressive builds.

4. Strong Structural Performance: Forged Durability

While styling is a key focus, Forgex Speed’s 2-Piece Forged Wheels don’t compromise on structural performance—thanks to the 12K-Ton Forging process and 6061-T6 aluminum construction. Some enthusiasts worry that modular wheels are weaker than monoblock alternatives, but Forgex Speed’s engineering eliminates this concern. Both the center section and barrel are forged under 12,000 tons of pressure, which compacts the aluminum to create a dense, strong structure with aligned grain flow.

The 6061-T6 aluminum alloy is renowned for its exceptional tensile strength (42,000 psi) and yield strength (35,000 psi), making it ideal for automotive wheels that must withstand road impacts, cornering forces, and weight loads. The center section—where the wheel attaches to the hub—is forged to be thicker and more robust, ensuring a secure connection to the vehicle. The barrel is engineered to resist bending and flexing, even under hard cornering or rough road conditions. The connection between center and barrel uses high-strength bolts that are torque-tightened to exact specifications, creating a joint that’s nearly as strong as a single piece. Every set of 2-Piece Forged Wheels undergoes rigorous testing, including load-bearing tests and impact tests, to ensure they meet or exceed industry safety standards. For drivers who want both style and peace of mind, this structural performance is a critical advantage.

5. Easy Repair and Maintenance: Extend Wheel Lifespan

Forgex Speed’s 2-Piece Forged Wheels offer a unique advantage over monoblock wheels: easy repair and maintenance that extends their lifespan. Wheels are prone to damage from curb rash, potholes, or road debris—and with monoblock wheels, even a small scratch or bend often means replacing the entire wheel. With 2-Piece Forged Wheels, however, you can replace just the damaged component (center or barrel) rather than the whole wheel.

For example, if you scrape the barrel on a curb, you can simply order a new barrel and reattach it to the undamaged center—saving you time and money. The modular design also makes maintenance easier: you can remove the barrel to clean hard-to-reach areas between the center and barrel, preventing dirt and debris from building up and causing corrosion. Hardware can be replaced individually if it becomes worn or damaged, and the separate components make it easier to refinish the wheels (e.g., repainting the center or polishing the barrel) without disassembling the entire wheel. This repairability and ease of maintenance mean Forgex Speed’s 2-Piece Forged Wheels can last for years, even with regular street use. For enthusiasts who invest in premium wheels, this ability to extend lifespan is a significant benefit.

Process Selling Points: Core Technologies of Forgex Speed 2-Piece Forged Wheels

1. 12K-Ton Forging for Both Center and Barrel: Uniform Strength

The foundation of Forgex Speed’s 2-Piece Forged Wheels is the 12K-Ton Forging process, which is applied to both the center section and the barrel to ensure uniform strength across the entire wheel. Forging involves heating 6061-T6 aluminum billets to a precise malleable temperature (around 900°F) before compressing them under 12,000 tons of pressure into custom molds for the center and barrel. This extreme pressure eliminates internal voids, air pockets, and inconsistencies that are common in cast wheels, creating a material structure that’s up to 30% denser.

What makes this process critical for 2-Piece Forged Wheels is the grain alignment it creates. For the center section, grains flow outward from the hub to the spokes, reinforcing the areas that bear the most load. For the barrel, grains wrap around the circumference, enhancing rigidity and resistance to bending. Forgex Speed uses computer-controlled forging presses to ensure consistent pressure and temperature for every component, so each center and barrel has the same strength and performance. After forging, each component undergoes X-ray and ultrasonic inspections to detect any internal defects—ensuring only flawless parts are used in assembly. This commitment to forging quality is what makes these 2-Piece Forged Wheels as strong as they are stylish.

2. Premium 6061-T6 Aluminum: The Ideal Modular Material

Forgex Speed’s choice of premium 6061-T6 aluminum is a key factor in the performance of their 2-Piece Forged Wheels, as it offers the perfect balance of strength, workability, and corrosion resistance for modular design. 6061-T6 is a heat-treated aluminum alloy composed of aluminum, magnesium, and silicon—elements that combine to create a material that’s both strong enough to withstand forging and flexible enough to be machined into intricate shapes.

The “T6” heat treatment (solution heat treatment followed by artificial aging) strengthens the alloy by forming microscopic precipitates that block metal dislocation, increasing its tensile and yield strength. This means the center and barrel can be forged into thin, lightweight designs without sacrificing durability—critical for 2-Piece Forged Wheels that need to be both strong and stylish. 6061-T6 is also highly machinable, allowing Forgex Speed to create precise mounting points on the center (for hub attachment) and barrel (for bolt connections) with tight tolerances. Additionally, the alloy’s natural corrosion resistance is enhanced by Forgex Speed’s finishing processes, ensuring the wheels resist rust and wear even in harsh weather conditions. For modular wheels that need to perform as well as they look, 6061-T6 aluminum is the ideal choice.

3. Precision Modular Assembly: Secure and Consistent Connection

Precision modular assembly is a critical technology that ensures the center and barrel of Forgex Speed’s 2-Piece Forged Wheels form a secure, consistent connection. The modular design relies on a flange-and-bolt system: the center section has a raised flange that mates with a corresponding groove in the barrel, and high-strength bolts (typically 12-16 per wheel) are used to fasten the two components together.

Forgex Speed uses CNC-machined flanges and bolt holes to ensure a perfect fit—tolerances are kept to ±0.001 inches to prevent gaps or misalignment between center and barrel. The bolts are made from high-grade materials like titanium or stainless steel, which offer exceptional strength and corrosion resistance. Each bolt is torque-tightened to exact specifications (using computerized torque wrenches) to ensure uniform pressure across the flange, creating a joint that’s resistant to vibration and separation. After assembly, each wheel undergoes a dynamic balance test to ensure it spins smoothly at high speeds—critical for ride comfort and tire wear. This precision assembly process eliminates the “weak link” concern often associated with modular wheels, ensuring Forgex Speed’s 2-Piece Forged Wheels are as reliable as they are customizable.

4. Deep-Lip Forging and Machining: Perfect Profile Creation

Creating the perfect deep-lip profile for 2-Piece Forged Wheels requires specialized forging and machining techniques that Forgex Speed has mastered. Deep lips are challenging to produce because they require the barrel to have a thin, curved outer edge while maintaining strength—but Forgex Speed’s 12K-Ton Forging process and precision CNC machining make it possible.

The barrel forging mold is designed with a curved cavity that shapes the aluminum into the desired lip depth—from 1 inch to 4 inches. After forging, the barrel is mounted on a CNC lathe, where tools shape the lip into a smooth, consistent curve. The inner edge of the barrel is machined to create the groove that mates with the center’s flange, ensuring a secure fit. Forgex Speed also offers “stepped” lip designs (where the lip has multiple curves) for a more dramatic look—these are created using multi-axis CNC machining that shapes the lip in multiple passes. The result is a deep lip that’s both visually striking and structurally sound—no uneven edges, weak points, or inconsistencies. This attention to detail in forging and machining is what makes Forgex Speed’s deep-lip 2-Piece Forged Wheels stand out from cheaper, cast alternatives.

5. Premium Finishing Processes: Protect and Personalize

Forgex Speed’s 2-Piece Forged Wheels undergo premium finishing processes that protect the aluminum, enhance aesthetics, and allow for further personalization. After forging and machining, each center and barrel is thoroughly cleaned to remove debris, then treated with a pre-finish process (like zinc phosphate) to improve coating adhesion. Forgex Speed offers a range of finish options, each tailored to different styles and durability needs.

Powder coating is the most popular choice, available in matte, satin, and gloss finishes in hundreds of colors—from classic black and silver to custom hues like candy red or metallic blue. Anodization is another option, creating a thin, porous oxide layer that can be dyed in vibrant colors and offers exceptional corrosion resistance. For a luxurious look, Forgex Speed offers PVD (Physical Vapor Deposition) coating, which creates a mirror-like finish in gold, chrome, or black that’s more durable than traditional chrome plating. The modular design allows for “two-tone” finishes—for example, a black powder-coated center with a polished aluminum barrel—adding another layer of personalization. All finishes are cured at high temperatures to ensure they bond permanently to the aluminum, and every wheel undergoes a quality check to ensure uniformity and flawlessness. These finishing processes not only protect the wheels but also let enthusiasts fully customize their look.

Conclusion

Forgex Speed’s 2-Piece Forged Wheels redefine what’s possible in automotive wheel customization, merging modular flexibility with premium forging quality to deliver wheels that are as stylish as they are strong. Their core advantages—unmatched styling flexibility, deep-lip construction, adjustable fitment, strong structural performance, and easy maintenance—make them the ideal choice for enthusiasts building VIP sedans, widebody sports cars, stance projects, or showstopping custom vehicles. Unlike monoblock wheels that limit creativity, these 2-Piece Forged Wheels put control in the hands of the builder, allowing for endless combinations of centers, lips, hardware, and finishes.

The advanced technologies behind these wheels—from the 12K-Ton Forging process that ensures uniform strength to precision modular assembly that creates a secure joint—are a testament to Forgex Speed’s commitment to quality. Every component is engineered and tested to exceed industry standards, ensuring the wheels perform reliably on the street while turning heads at car shows. For anyone who wants wheels that reflect their unique style without compromising on strength or fitment, Forgex Speed’s 2-Piece Forged Wheels are the ultimate investment. They aren’t just a part of the vehicle—they’re a statement of individuality, craftsmanship, and performance that elevates any custom build to new heights.